Event Date

Speaker: Gregory George, Applications Engineering Manager of Oqton

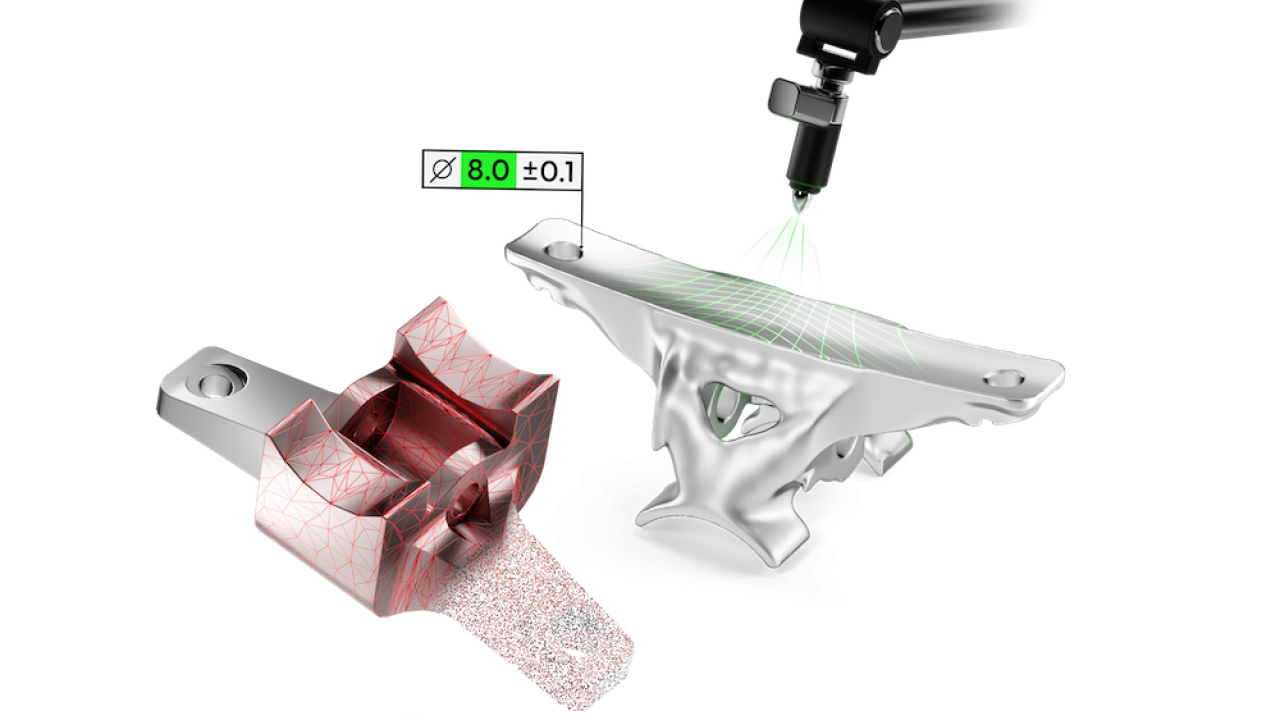

3D Scanning is the process of converting physical, real-world objects into precise digital models, for various applications. Integration of 3D scan-based technology into any production environment provides the perfect platform to supercharge product manufacture through fast digitization, geometry optimization and accurate quality assurance.

Whether you're recreating a legacy part, or taking your prototype to mass production, 3D Scanning empowers teams across your production to design and manufacture accurate parts, faster and more flexibly than ever before. 3D Scanning has huge potential in manufacturing optimization across a range of industries, including Aerospace, Automotive and Consumer Products.

In this webinar, we’ve brought together experts from Hexagon and Geomagic, developed by Oqton, to walk you through the custom redesign, manufacture and quality assurance of an integral recumbent bicycle component.

If you're going to invest in powerful 3D scanning hardware, then investing in an equally powerful Reverse Engineering and Inspection software is a non-negotiable. By the end of this webinar, you will learn:

- How introducing 3D Scanning technology into your production process can yield optimal parts with fewer design iterations.

- Best practices and top tips for scanning components to maximise accuracy and minimize rescanning.

- How the right Reverse Engineering toolset can seamlessly bridge the gap between data collection and CAD design, to manufacture parts that fit right first time, every time.

- The benefits of scan-based inspection, and how integrating professional, flexible data collection and analysis WILL improve your production efficiency.